PRODUCTS

Product Category

TYD Diposable Food Container (Thin.Wall Products) Manufacture Machine Series

Item No.:

C-001

Category:

Summary

Big space between tie-tars and opening stroke, for bigger size of moulds.Plug-in card type ejection undercling structure, for mould ejecting restoration.

Description

TYD series servo energy saving injecion moulding machine is researched and designed by Taiyide technology team. TYD machine not only inherited the advantages of energy saving, precise control, fast response and reliable performance from traditional TYD machine, also made great improvements in repeatability, plasticizing speed, power comsumption and machine noise. With all those advantages, leading technology implementation. TYD machine has got technology design patents.

High Response Servo Motor

Because using high response servo motor and internal gear pump force system, the machine achieve maximum output 0.05s.

Compared to traditional injection moulding machines, the response speed is faster. Time is shortened and increase the produce efficiency.

Comparison of Repetitive Precision

Superposition of servo motor' s precision and the internal gear pump’s precision, through the high sensitive pressure feed

back device to form closed loop. The repetitive precision of the machies is up to 3‰. And compared to traditional hydraulic

injection moulding machines showing greater injection stability.

|

STANDARDS |

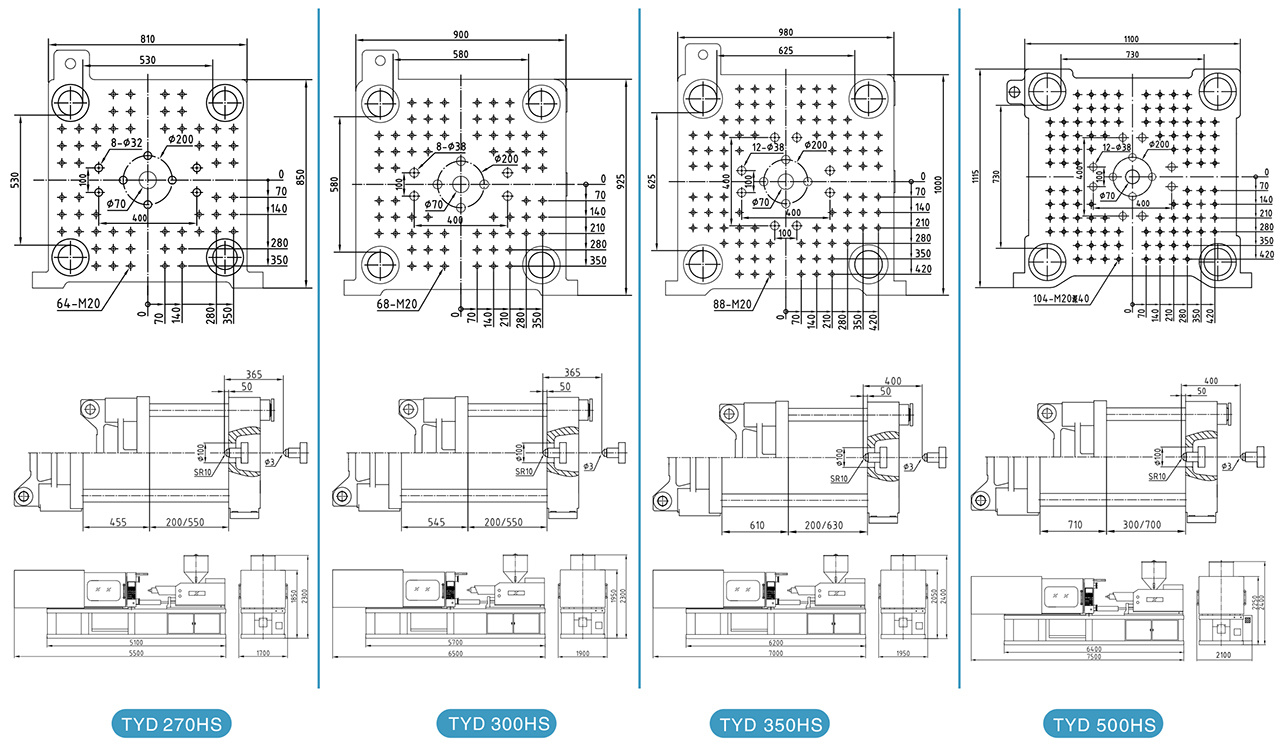

TYD 270HS |

TYD 300HS |

TYD 350HS |

TYD 500HS |

||

|

Injection Unit |

unit |

B |

B |

B |

Single cylinder | Double Cylinder |

|

Screw Diameter |

mm |

φ40 |

φ45 |

φ50 |

φ50 |

①55 |

|

Screw Ratio |

L/D |

27 |

25 |

23 |

25 |

28 |

|

Theoretical Injection Volume |

cm³ |

282 |

397 |

530 |

390 |

640 |

|

Theoretical Injection Weight(PS |

g |

257 |

328 |

438 |

355 |

580 |

|

njection Pressure |

Mpa |

192 |

207 |

169 |

155 |

168 |

|

Injection Rate |

g/s |

310 |

436 |

350 |

340 |

350 |

|

Injection Stroke |

mm |

225 |

250 |

270 |

200 |

270 |

|

Screw Speed |

rpm |

0-400 |

0-400 |

0-400 |

0-400 |

|

|

Clamping Unit |

|

|

|

|

|

|

|

Clamping Force |

KN |

2700 |

3000 |

3500 |

5000 |

|

|

Opening Stroke |

mm |

455 |

545 |

610 |

710 |

|

|

Mold Thickness(min-max) |

mm |

200-550 |

200-550 |

350-630 |

300-700 |

|

|

Space Between Tie Bars(WxH) |

mm |

530X530 |

580X580 |

625X625 |

730X730 |

|

|

Ejection Force |

KN |

80 |

80 |

80 |

80 |

|

|

Ejection Stroke |

mm |

125 |

160 |

160 |

160 |

|

|

Ejector Number |

P |

8+1 |

8+1 |

12+1 |

2+1 |

|

|

Others |

|

|

|

|

|

|

|

Max.Hydraulic System Pressure |

Mpa |

16 |

16 |

16 |

16 |

|

|

Pump Driving Power |

KW |

45 |

45x2 |

55x2 |

55x2 |

|

|

Heating Power |

KW |

14.3 |

18.8 |

24.5 |

24.5 |

|

|

Oil Tank Capacity |

|

620 |

850 |

900 |

900 |

|

|

Machine Dimension[Lx W×H] |

m |

5.5X1.7X2.3 |

7.2X1.9X2.3 |

7.5X1.95X2.4 |

75X20X24 |

|

|

Machine Weigh |

|

9.3 |

11.5 |

14.5 |

18.5 |

|

● Please inform us when you have other special requirements.

● The above data are for reference only, Taiyide may subject to change without prior notes.

Online Message

Thank you for your attention to us. If you have any needs or comments, please leave us a message.